Sucking sound with a big popping sound at shut down

#21

Ok, I think this sound is from the butterfly valve between the main hose for the cold air intake and the top of the motor. It is so odd sounding I'm sure I would have heard this before the CEL came on had it been a typical sound. So. I'm just taking it to the Hummer service department tomorrow morning.

#23

I just returned from the Hummer Service Department. The K&N filter system was installed properly by me a few days ago. The Service tech agreed. He ran the computer thru some tests and found that the CEL came on because the K&N caused the motor to run to lean. So I had to have it removed. What a big disappointment. I called Kragen to ask if they will take it back as it will not work on my H3 the woman told me "no not if you've already installed it" well duh. It should have some kind of guaranty right?

#24

Well that sucks.....but I don't get why the K&N would cause any problems , there's allot of people on this forum with this kind of setup, like I mentioned in one of my post that I'm running the True Flow system and it's very similar to the K&N and my H3 is a 2006. If I were you I would call K&N direct and explain to them whats going on, P.S. they are a sponsor on this forum so that can give you a little pull....good luck.

, there's allot of people on this forum with this kind of setup, like I mentioned in one of my post that I'm running the True Flow system and it's very similar to the K&N and my H3 is a 2006. If I were you I would call K&N direct and explain to them whats going on, P.S. they are a sponsor on this forum so that can give you a little pull....good luck.

, there's allot of people on this forum with this kind of setup, like I mentioned in one of my post that I'm running the True Flow system and it's very similar to the K&N and my H3 is a 2006. If I were you I would call K&N direct and explain to them whats going on, P.S. they are a sponsor on this forum so that can give you a little pull....good luck.

, there's allot of people on this forum with this kind of setup, like I mentioned in one of my post that I'm running the True Flow system and it's very similar to the K&N and my H3 is a 2006. If I were you I would call K&N direct and explain to them whats going on, P.S. they are a sponsor on this forum so that can give you a little pull....good luck.

#25

Sure, you're going to run lean when you first install the intake - that's the whole point. More air in means more fuel needs to be added by the PCM which makes more power. Free-flow intakes initially create a lean condition because they draw in more air than the more restrictive stock setup. What happens next is the PCM discovers this because the oxygen sensor in the exhaust is registering higher oxygen content than desired which means it's not being burned in combustion. The PCM sees this as a need to add more fuel to balance the air/fuel ratio back as close to 14.7:1 as possible (stoichiometric or ideal air/fuel ratio) and so slowlyadjusts the short and long term fuel trims until balance is restored. Increasing fuel trims is accomplished by extending injector pulse width to ensure the right amount of fuel is added to the increased air flow into the cylinders. More air + more fuel = more power.

Running lean to the degree that a free-flow or CA intake will result in will not usually get anywhere near causing damage to the engine. In my vette, the fuel trims can very +20% with no ill consequenses. At that point I'll step in and make a manual adjustment to the injector flow rate using my tuning software to make a gross tweakand then drive the car fora while and let the PCM make progressive adjustments to the trims until they have essentially zeroed out again.

You see, the PCM is constantly learning and making adjustments to fine tune the engine to optimize efficiency and power. When you add the new intake, you introduce more oxygen, which is good. You simply need to ensure there are no leaks so unmetered air doesn't enter after the MAF and into the manifold so the PCM has an accurate accounting of how much fuel it needs to add to optimize air/fuel. A CEL can often be set by a very small amount of unmetered air being added to the system. Remember, too, that under the high vacuum of low RPM operation, the proportion of unmetered air enteringcaused by even a small leak can be substantial and that will certainly set a CEL sooner than later.

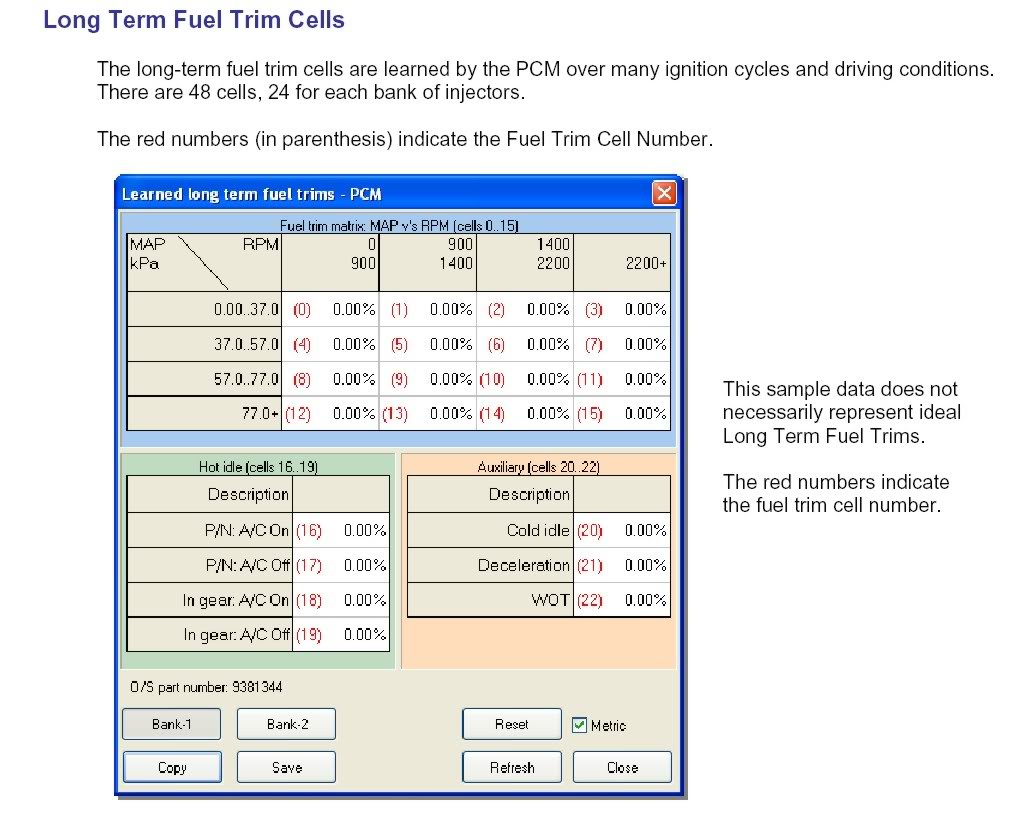

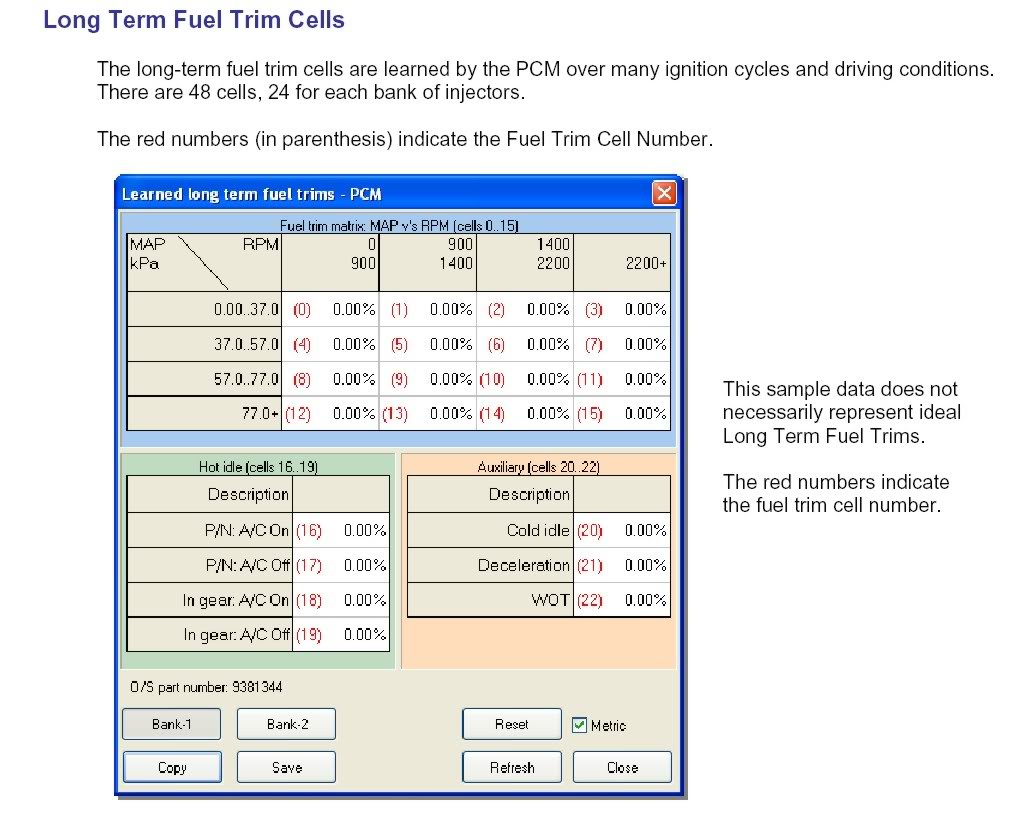

Resetting the computer by disconnecting the battery is usually recommended when installing a new intake as it resets the short and long term fuel trims back to zero and gives a better chance of not setting a CEL. Generally, your trims are not going to be perfect when you do install a new intake and the values that are there may throw you in error enough to throw a CEL before the PCM has had a chance to relearn the new air flow and compensate. Here's a page from my tuning sw user manual that shows the fuel trim table as it appears when it's zeroed out which is optimal. The zeroes indicate no trim adjustments are necessary and the fuel flow rate is set where it needs to be. You will never see this in real life since there is no such thing as an engine that runs perfectly in every RPM range and mode. Zero is the goal. (Note: This table is for a V8 LS1/6 so there are two banks of cylinders, etc.)

So, you did the right thing disconnecting the battery to reset the trims and let the PCM relearn the new air flow. You'll need to drive around a while to let this happen. If you set another CEL, I would start looking for anolmalies in the air tract or some other issue. The fact that the CEL went out indicates the MAF sensor is most likely not damaged so I would look for restrictions in throttle plate movement or leaks causing unmetered air to enter the engine. Also, get a buddy to help so you can look and listen to the engine with the hood up while he/she runs the engine so you can be right at the engine to look or listen for problems.

But I would certainly not give up and return the intake - chances are you're close to finding the problem.

Running lean to the degree that a free-flow or CA intake will result in will not usually get anywhere near causing damage to the engine. In my vette, the fuel trims can very +20% with no ill consequenses. At that point I'll step in and make a manual adjustment to the injector flow rate using my tuning software to make a gross tweakand then drive the car fora while and let the PCM make progressive adjustments to the trims until they have essentially zeroed out again.

You see, the PCM is constantly learning and making adjustments to fine tune the engine to optimize efficiency and power. When you add the new intake, you introduce more oxygen, which is good. You simply need to ensure there are no leaks so unmetered air doesn't enter after the MAF and into the manifold so the PCM has an accurate accounting of how much fuel it needs to add to optimize air/fuel. A CEL can often be set by a very small amount of unmetered air being added to the system. Remember, too, that under the high vacuum of low RPM operation, the proportion of unmetered air enteringcaused by even a small leak can be substantial and that will certainly set a CEL sooner than later.

Resetting the computer by disconnecting the battery is usually recommended when installing a new intake as it resets the short and long term fuel trims back to zero and gives a better chance of not setting a CEL. Generally, your trims are not going to be perfect when you do install a new intake and the values that are there may throw you in error enough to throw a CEL before the PCM has had a chance to relearn the new air flow and compensate. Here's a page from my tuning sw user manual that shows the fuel trim table as it appears when it's zeroed out which is optimal. The zeroes indicate no trim adjustments are necessary and the fuel flow rate is set where it needs to be. You will never see this in real life since there is no such thing as an engine that runs perfectly in every RPM range and mode. Zero is the goal. (Note: This table is for a V8 LS1/6 so there are two banks of cylinders, etc.)

So, you did the right thing disconnecting the battery to reset the trims and let the PCM relearn the new air flow. You'll need to drive around a while to let this happen. If you set another CEL, I would start looking for anolmalies in the air tract or some other issue. The fact that the CEL went out indicates the MAF sensor is most likely not damaged so I would look for restrictions in throttle plate movement or leaks causing unmetered air to enter the engine. Also, get a buddy to help so you can look and listen to the engine with the hood up while he/she runs the engine so you can be right at the engine to look or listen for problems.

But I would certainly not give up and return the intake - chances are you're close to finding the problem.

#26

Well fortunately Hummer took a close look at my system like I did last night. I spayed ether around all the fittings. No change in idle at all. So, I had no leaks. Also after I reset the CEL last night the light stayed off until maybe a half hour or less of driving, then bingo I looked down to see the CEL come on. Big bummer. But Hummer did many tests and kept the truck for at least 6 hours, and the only thing they could find was the new intake. So they were kind enough to swap out the new for the old no charge. But pretty much told me they never had such a problem before and said it was the new intake at fault.

#27

So, I take it no CEL since the return to stock? That would lead me to think there is possibly a problem with the new intake itself. The popping sound is a clue - excess vacuum perhaps caused by an unintended restriction due to a defect in the system?

I have done, and seen done, some pretty radical intake mods withany problem that wasn't transient and short-lived. I did have one twin-cone intake on my vette once that caused it to go way too lean to the point I had to remove it. But an even more free-flow one replaced that and worked with no problem. The twin-cone was apparently creating turbulence at the MAF that the PCM could not resolve. It never did set a CEL though.

Best of luck in resolving your issue.

I have done, and seen done, some pretty radical intake mods withany problem that wasn't transient and short-lived. I did have one twin-cone intake on my vette once that caused it to go way too lean to the point I had to remove it. But an even more free-flow one replaced that and worked with no problem. The twin-cone was apparently creating turbulence at the MAF that the PCM could not resolve. It never did set a CEL though.

Best of luck in resolving your issue.

#28

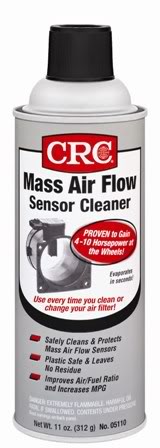

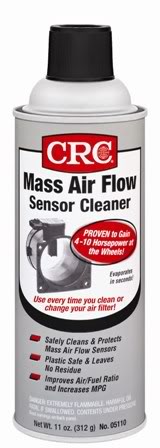

Do not spray either or electronic cleaner on your MAF. If you think it is dirty (I read where you said it looks clean) use MAF cleaner.

Patches provided some good info on PCM box learning, but note that it takes a while, maybe as much as atank or two of gas tolearn as much as capable.

The POPPING sound is perfectly normal..vacuum releasing a diaphram, you've had it all along just never heard it with the stock system as you suspected. There are threads on it if you SEARCH. This ain't rocket science. The K&N CAI (misnomer to be sure) makes racket, and I personally hate that barricade in the corner concept, flow benefits are offset by under hood temps. [:@]

Give your air filter a 180° turn and make sure (again) your MAF is mounted correctly and is not getting any airleak past it.

Get a PCMforless tune set for an intake system and use your K&N, OR get a better intake and ebay yours.

Patches provided some good info on PCM box learning, but note that it takes a while, maybe as much as atank or two of gas tolearn as much as capable.

The POPPING sound is perfectly normal..vacuum releasing a diaphram, you've had it all along just never heard it with the stock system as you suspected. There are threads on it if you SEARCH. This ain't rocket science. The K&N CAI (misnomer to be sure) makes racket, and I personally hate that barricade in the corner concept, flow benefits are offset by under hood temps. [:@]

Give your air filter a 180° turn and make sure (again) your MAF is mounted correctly and is not getting any airleak past it.

Get a PCMforless tune set for an intake system and use your K&N, OR get a better intake and ebay yours.

#29

ORIGINAL: blackbear

Well that sucks.....but I don't get why the K&N would cause any problems , there's allot of people on this forum with this kind of setup, like I mentioned in one of my post that I'm running the True Flow system and it's very similar to the K&N and my H3 is a 2006.

, there's allot of people on this forum with this kind of setup, like I mentioned in one of my post that I'm running the True Flow system and it's very similar to the K&N and my H3 is a 2006.

Well that sucks.....but I don't get why the K&N would cause any problems

, there's allot of people on this forum with this kind of setup, like I mentioned in one of my post that I'm running the True Flow system and it's very similar to the K&N and my H3 is a 2006.

, there's allot of people on this forum with this kind of setup, like I mentioned in one of my post that I'm running the True Flow system and it's very similar to the K&N and my H3 is a 2006.

True Flow's filter is foam. K&N's is oiled cotton gauze. Each has certain pros and cons, but IMO I like the K&N filter better.

The K&N CAI, like many others, gos to a ridiculous extent to build a heat shield to: 1)allegedly capture cool air from around the headlight area in the front corner of the engine bay with rubber or foam weather strip doohicky touching the hood, but yet DO NOT seal where their intake pipe goes thru the heat shield [just look at the Brut Force intake for another classic example]; and 2) and replaces the factory air filter box requiring relocation of the MAF in their plastic pipe.

True Flow calls theirs a "sealed" system as it uses silicone couplers to flow air thru a 3" metal pipe (the good part) and relies on the stock approach to pull in are shielded away from the underhood engine heat by the inner fender. That inner fender is open to the fake air intake cover in the rear and catches air from around the turn signal and grill. I like True Flows' approach better, but they left power on the table in at least two ways (3" pipe is smaller then the rest of the system at 3.6"=air filter box to 3.4"=throttle body inlet) and the air filter box inlet snorkel was left stock...also 3". True Flow does not customer support the vibration noise a multitude of their customers have experienced caused by that stock air filter box inlet snorkel contacting the fender.

OK Iover did it, but I know the intake system, and I know how to improve it.

#30

Doc, thanks for the info: when I said very similar to the K&N, I was talking about the setup, if I not mistaken both K&N and True Flow come packed in a oily goop from the factory, that's what I was suggesting more then anything, I was thinking that maybe he got some of that crap on his sensor.[/align][/align]For me, one of the main reasons I went with the True Flow is that they use the factory filter box, I do allot of offroading and find my self in water often, the open concept from K&N to me could cause problems when in deep water.[/align]