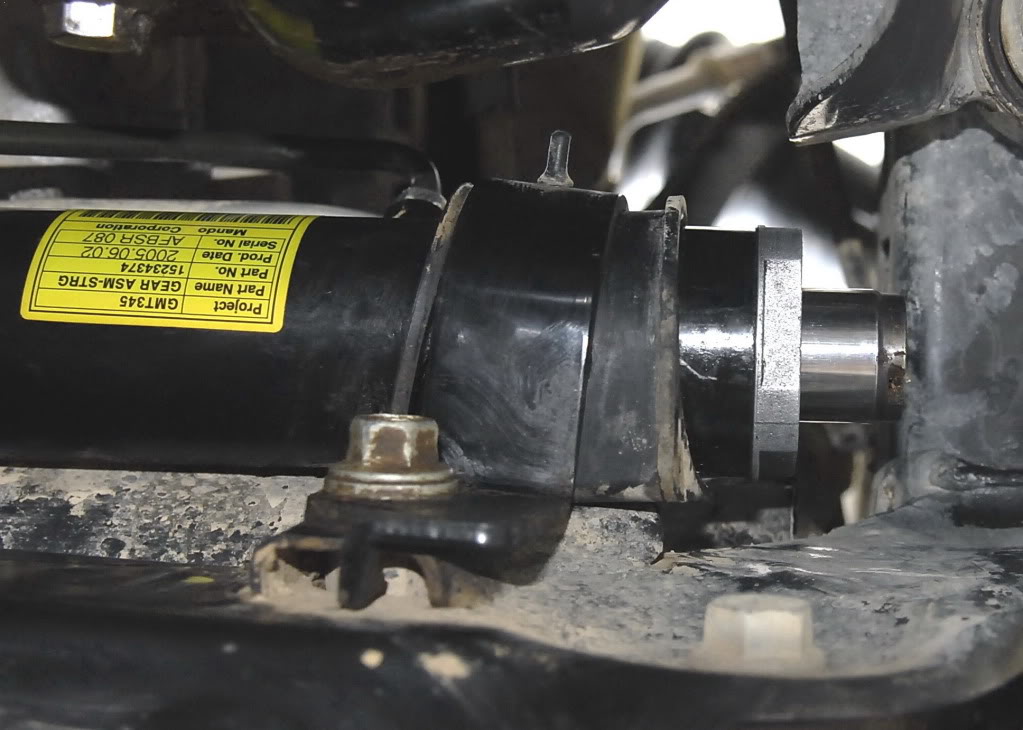

Rack and Pinion Movement

#2

I would say there should be no slop in the rack to frame bushings, howerver my 07 H3's passenger side bushing does have some lateral motion on a lift ,suspension hanging.....when you wiggle wheel left to right ....needs a poly bushing in my opinion

#7

Thanks for all the input. I had the GM dealer check it over after alignment shop said it needed new bushings. Dealer said everything was tight. I brought it home and had my wife turn steering wheel back and forth while I looked at rack. Passenger side bushing had some movement, but through bolt on driver side had enough slop to allow rack to make knocking sound. Took it back to dealer, showed them what I found and they agreed, ordered new rack, and replaced it. I found out that when they checked it, they only checked it up on lift. Which showed things were tight. Only when loaded with weight could the slop be seen.

#8

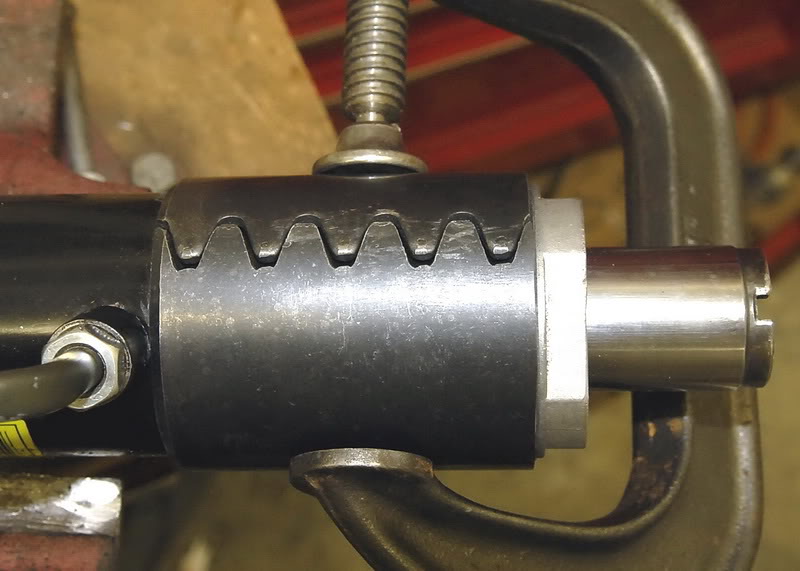

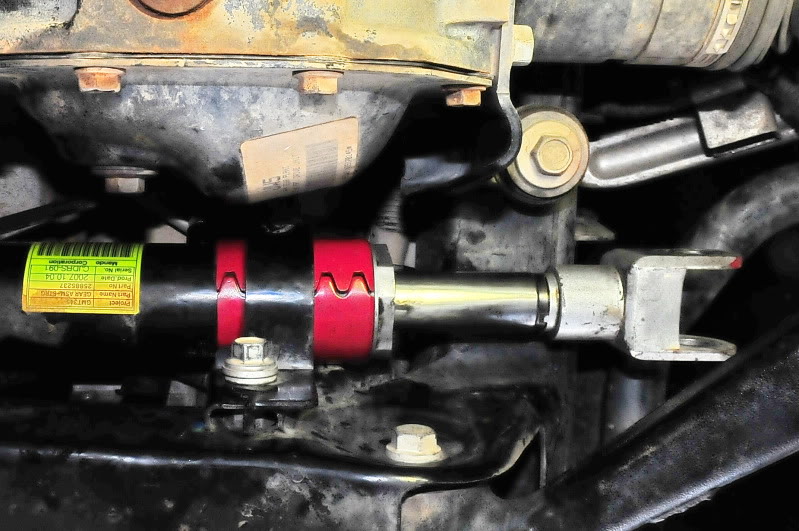

I couldn't stand it any longer and even though like 999 got boring I thought I would respond. It seems that you have to find the right place to find the slack. Sometimes when on the ground it gets in a place that it is not in a bind and will move or sometimes when jacked up you can do the hands behind the tire and one in front and push pull to see it move. After awhile it can loosen the other end by flexing those rubber inserts OR break the rack. I still have a few of the sleeves left that are two inches long to fit between the OEM tie rod boots and the hydraulic nipple.

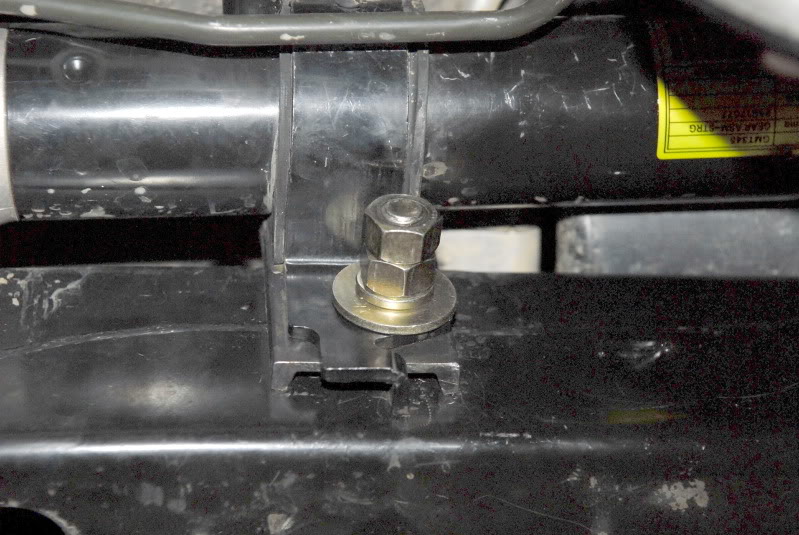

This shot is with my BP tie rods and I made some boots. This was before I trimmed the extra threaded bolt on the clamp, as once I do it will be too short to reuse. It was just the only shot I could find right now.

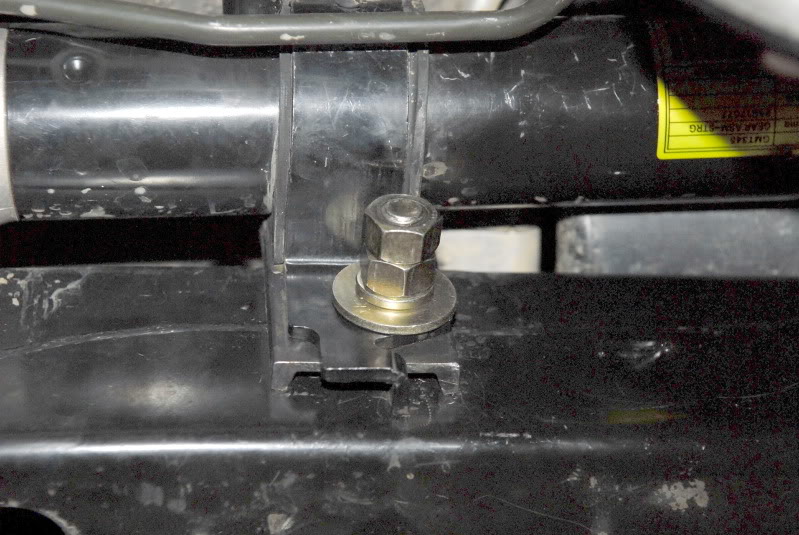

The ultimate fix would be to add a center bracket to help hold the thing in place.

This shot is with my BP tie rods and I made some boots. This was before I trimmed the extra threaded bolt on the clamp, as once I do it will be too short to reuse. It was just the only shot I could find right now.

The ultimate fix would be to add a center bracket to help hold the thing in place.

Last edited by Hunner; 12-19-2011 at 09:00 PM.

#9

It looks good but with being a solid metal instead of a flexible rubber/poly, isn't it effecting anything on the steering ? It might scratches the rack as the rack flexes, but otherwise it is fine ?

What is the diameter of the rack ? Can I use something like a Rod bearing there if the thickness is correct ? If I use a good lithium grease, will that work ?

What is the diameter of the rack ? Can I use something like a Rod bearing there if the thickness is correct ? If I use a good lithium grease, will that work ?